In the dynamic realm of automotive manufacturing, precision and quality are paramount. Imagine a world where every component of your car, from the engine to the smallest gears, functions flawlessly and without compromise.

This vision isn’t just a dream but a reality, thanks to Cleanroom Molding. Here in this article, we’ll delve into the significance of Cleanroom Molding Small Batch in the automotive industry and why it’s pivotal for meeting the stringent quality standards demanded by both manufacturers and consumers.

Cleanroom Molding Explained

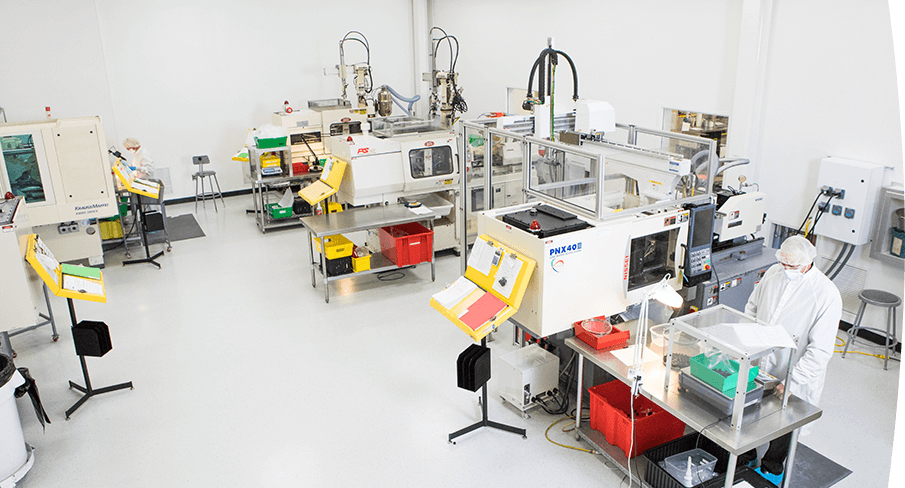

Before we dive into the why, let’s understand the what. Cleanroom molding is a specialized manufacturing process that takes place within a controlled environment designed to minimize contaminants like dust, microbes, and foreign particles.

These environments are maintained at specific temperatures, humidity, and cleanliness levels. In essence, it’s a hermetically sealed cocoon where precision reigns supreme.

Cleanroom molding isn’t just about keeping things squeaky clean. It’s the linchpin of quality assurance in automotive manufacturing. The smallest impurity can lead to significant defects in components, compromising the performance, safety, and longevity of vehicles.

But with Cleanroom Molding Small Batch, the risk of contaminants wreaking havoc on automotive parts is dramatically reduced.

Benefits for the Automotive Industry

Cleanroom molding is a game-changer for the automotive sector. Here are the key benefits:

1. Precision Engineering: Cleanroom environments allow for the production of automotive components with unparalleled precision. It means parts fit together seamlessly, reducing the risk of malfunctions and increasing overall vehicle performance.

2. Consistency Matters: Inconsistent parts can lead to assembly line bottlenecks and increased production costs. Cleanroom Molding Small Batch ensures a high level of consistency, reducing variations and speeding up manufacturing processes.

3. Enhanced Product Reliability: Automotive manufacturers rely on the durability and reliability of their vehicles. Cleanroom molding minimizes defects to make automotive parts less likely to fail, enhancing overall product reliability.

4. Reduced Defects and Recalls: One of the most significant benefits is the substantially reduced defects. Fewer defects mean fewer recalls, saving manufacturers significant costs and preserving their reputation for quality.

5. Improved Safety: Vehicle safety is paramount, and cleanroom molding helps ensure that critical safety components, such as airbag housings and braking system parts, meet the highest quality standards, reducing the risk of accidents due to component failure.

6. Lower Environmental Impact: As the automotive industry seeks to reduce its environmental footprint, cleanroom molding plays a role. Minimizing waste and defects contributes to a more sustainable manufacturing process.

7. Positive Brand Image: Consistently producing high-quality vehicles builds a strong brand image. Cleanroom molding can help automakers establish themselves as leaders in quality and innovation, attracting discerning customers.

8. Efficiency Gains: Cleaner environments reduce the need for frequent equipment maintenance and cleaning, resulting in less downtime and increased overall production efficiency.

9. Meeting Regulatory Requirements: The automotive industry is subject to strict regulatory standards. Cleanroom molding helps manufacturers meet these requirements and ensure their vehicles comply with safety and emissions regulations.

10. Competitive Edge: The ability to produce vehicles of exceptional quality can be a significant competitive advantage in a crowded market. Cleanroom Molding provides this edge, helping companies stand out.

Hence, cleanroom molding is not just a manufacturing technique but a strategic investment for the automotive industry. Its benefits extend beyond the factory floor, positively impacting product quality, safety, efficiency, and the bottom line.

Regulatory Compliance

The automotive industry is a tightly regulated space. Governments and international bodies set stringent standards for vehicle safety and environmental impact.

Cleanroom molding helps automakers stay in compliance with these regulations. By operating in a controlled environment, manufacturers can trace and document the production process meticulously, ensuring each part meets the necessary standards.

Final Thoughts

Overall, in the ever-evolving automotive industry, cleanroom molding isn’t an option but a necessity. It’s the gateway to precision, quality, and compliance.

Automakers must rise to the occasion as consumers demand more from their vehicles. Cleanroom Molding Small Batch isn’t just a process but a commitment to excellence, a promise of a better, safer, and more reliable driving experience.

So, the next time you hit the road, remember that behind every smooth ride is the meticulous work that happens in a cleanroom.

Source’s Link:- https://theamberpost.com/post/importance-of-cleanroom-molding-in-automotive-industry