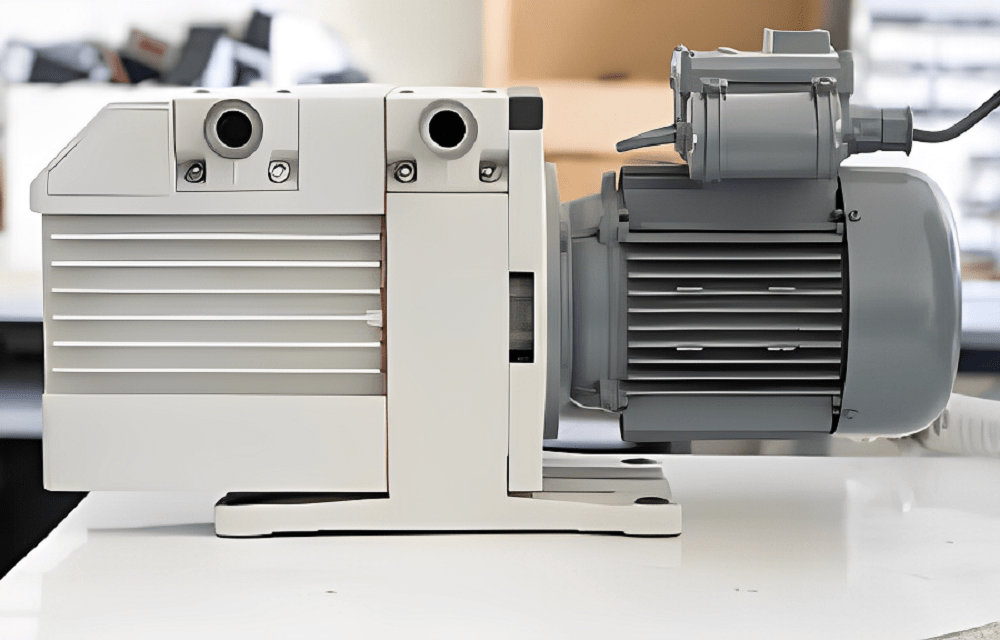

Breathing New Life: The Art of Vacuum Pump Repair

In the world of industrial machinery, where precision is paramount, the question often arises: Can a vacuum pump be repaired? The short answer is a resounding yes. Here, we’ll delve into the intricacies of vacuum pump repair, exploring the reasons behind potential issues, the repair process, and the transformative impact it can have on industrial operations.

Understanding Potential Issues:

Like any mechanical device, vacuum pumps are susceptible to wear and tear over time. Common issues include worn-out vanes, leaks, damaged seals, or problems with lubrication. These factors can impact the pump’s efficiency, leading to decreased performance and potentially disrupting industrial processes.

The Diagnostic Process:

The first step in repairing a vacuum pump involves a comprehensive diagnostic process. Skilled technicians use their expertise to analyze the pump’s performance, identifying the root causes of issues. This step is crucial in developing a targeted repair plan tailored to the specific needs of the pump.

Precision Repairs:

Once the diagnostic phase is complete, the repair process begins. Worn components are replaced, leaks are sealed, and lubrication is administered precisely. The goal is not just to fix the immediate issues but to restore the pump to optimal condition, ensuring it operates at peak efficiency.

Calibration for Efficiency:

Calibration is a critical aspect of the repair process. Technicians fine-tune the pump, adjusting parameters such as speed, vacuum levels, and pressure to ensure it operates within specified parameters. This step contributes to the overall efficiency and reliability of the vacuum pump.

Preventive Measures:

A comprehensive repair approach goes beyond fixing existing issues, including implementing preventive measures. This involves installing new filters, checking and adjusting tension on belts, and addressing potential problems that could arise. The goal is to future-proof the pump’s efficiency.

Cost-Effectiveness:

Choosing to repair a vacuum pump rather than replace it can be a cost-effective decision. The repair process is often more economical than investing in a new pump, especially when the issues are identified and addressed in a timely manner.

Conclusion: Breathing New Life into Operations

In conclusion, a vacuum pump can indeed be repaired, and the process involves a meticulous approach aimed at breathing new life into industrial operations. From diagnostics to precision repairs and preventive measures, the art of vacuum pump repair ensures that these essential devices continue to play a vital role in powering the efficiency of diverse industrial processes. Choosing repair saves costs and contributes to sustainability by extending the lifespan of valuable equipment.